Any links to online stores should be assumed to be affiliates. The company or PR agency provides all or most review samples. They have no control over my content, and I provide my honest opinion.

Every organization wants to increase their Return on Investment (RoI). However, with time, equipment starts to deteriorate in product value. They start working sloppy, provide worse quality, or in some instances, start malfunctioning.

To keep the production uninterrupted, it is essential to undergo factory equipment maintenance and keep them in the best working condition. CMMS helps keep track of every piece of equipment, manufacturer details, and keep the service history.

With CMMS, you can manage the maintenance team and tasks. It will ensure peak performance in machinery, thus manufacturing more products and increasing revenue and returns.

What is CMMS?

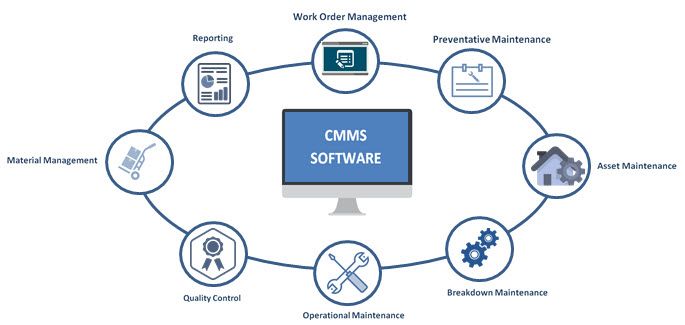

Computer Maintenance Management System (CMMS) is a software that helps to manage maintenance tasks through a single dashboard. It maintains the details of the maintenance activities of the maintenance team.

You can use it to track the maintenance team, work orders from the factory floor, equipment repairs, and schedule maintenance.

Let us look at how CMMS solutions can benefit the industry and enhance the Return on Investment.

How You Can Improve the RoI By Using A CMMS Solution

Better Communication

Sometimes, your company’s productivity may be affected due to communication issues. The standard procedure for a maintenance task execution is through a work order requested by the facility manager.

The traditional method of sending maintenance work orders is both exhausting and lacks proper communication. Moreover, there is always a chance of losing paper-based orders.

However, using CMMS gives better clarity in communication and ensure that both the Facility Manager and the Maintenance Manager are on the same page.

Without a clear goal for a task, it will take forever to complete it. CMMS resolves doubts and eliminates all the time spent on back and forth feedback, thus providing value through returns.

Better Maintenance Management

CMMS software enables better management of tasks through the use of tickets.

As a Maintenance Manager, you can look at all the maintenance tasks and their status through a common CMMS maintenance order database. You can check the status of the maintenance crew and their availability. It will help you to designate tasks to individuals with prowess on specific tasks.

Doing this will reduce maintenance time and increase quality. Hence, CMMS software can decrease idle time due to machine breakdowns and improve machine operability. It will also help reorganize the workforce, thus reducing costs and increasing productivity by employing them more productively.

Safety

The safety of every employee is the duty of a company. Moreover, there is also a need for product and process compliance in the industry.

Any untoward incident in the workplace can significantly affect company finances and reduce the morale of employees. Hence, it is essential to prevent mishaps and loss of life.

CMMS helps track assets and schedule preventive maintenance, and help prevent accidents and damage to life and property. After all, the best accident is the one that does not occur.

Product Compliance and Customer Satisfaction

A well-maintained machine increases the quality and quantity of end products. It also makes sure that they are compliant with standards. Thus, it prevents legal actions that may harm the reputation of the company and its future credibility.

Additionally, it increases customer satisfaction and trust with genuine products. Customer satisfaction helps to increase sales, which amounts to revenue. Thus, keeping the machine in peak condition by using CMMS can help to increase ROI.

Reduction in Energy Costs

Maintaining a machine with CMMS software can decrease losses caused due to overheating, friction, and other factors.

With a timely maintenance schedule, you can make sure that the machine is always well oiled. It will help you to reduce energy costs, as well as increase productivity.

It may seem like a trivial amount for a single machine for a day. However, if you consider the entire plant machinery for the whole of the year, the costs can skyrocket through the roof.

Training

As a Maintenance Manager, it pays to have an efficient team that can deal with all maintenance issues. However, not everyone is equally skilled in every task.

Hence, there are times when you will have to wait for a specific member of the crew to finish their work, even when other members are available but are unable to take up the task.

CMMS software helps you track your employees, including their maintenance tasks, attendance, and more. After analyzing the data, you can find out your maintenance crew’s weak points and train them.

It will grant you more options and decrease response time for maintenance, translating to reduced idle time on the factory floor.

Prediction and Forecasting

It is essential to keep the factory’s assets up to date and in the best working condition. Hence, it is necessary to undergo maintenance based on parts that need repairs. In many cases, neglecting a small repair work at an earlier date can have long term problems.

For example, an iron screw may rust and damage the operability of a machine. However, taking daily records and assessing parts can help you predict the parts’ maintenance, enabling you to purchase only those items that you need.

Thus, CMMS helps to reduce costs and increase the asset life cycle. It benefits the company since they do not need to replace an expensive machine. It also decreases or eliminates downtime caused by faulty equipment.

Service History and Warranty

CMMS has an extensive database, and unlike the pen-and-paper method, it can go back many years. It is also far easier to duplicate. Thus, the data is secure.

Additionally, it can preserve pictures of equipment after the previous servicing, technical drawing changes, and more. It may also include information about the last technician who serviced the machine.

The service history can give an accurate portrayal of the machinery’s condition and will help in dismantling and servicing without causing damage to equipment. The service history can also help repair a similar type of equipment.

Furthermore, the CMMS database contains the manufacturer details and product number. Hence, you can quickly call and ask the manufacturer for free service if it is within the warranty period.

Conclusion

The best predictive maintenance management software eliminating threats that are barely visible at the time. Moreover, it helps manage the maintenance crew for emergencies and train them so that a specialized maintenance crew member is always available to deal with specific problems. Thus, it prevents disruption in workflow and helps to keep productivity and returns on investment high.

I am James, a UK-based tech enthusiast and the Editor and Owner of Mighty Gadget, which I’ve proudly run since 2007. Passionate about all things technology, my expertise spans from computers and networking to mobile, wearables, and smart home devices.

As a fitness fanatic who loves running and cycling, I also have a keen interest in fitness-related technology, and I take every opportunity to cover this niche on my blog. My diverse interests allow me to bring a unique perspective to tech blogging, merging lifestyle, fitness, and the latest tech trends.

In my academic pursuits, I earned a BSc in Information Systems Design from UCLAN, before advancing my learning with a Master’s Degree in Computing. This advanced study also included Cisco CCNA accreditation, further demonstrating my commitment to understanding and staying ahead of the technology curve.

I’m proud to share that Vuelio has consistently ranked Mighty Gadget as one of the top technology blogs in the UK. With my dedication to technology and drive to share my insights, I aim to continue providing my readers with engaging and informative content.

Very nice article about CMMS software. I have used Innomaint CMMS for my business. Include that in your list. more details visit their site