Any links to online stores should be assumed to be affiliates. The company or PR agency provides all or most review samples. They have no control over my content, and I provide my honest opinion.

The Halot One Plus is the third printer in Creality’s Halot One series, providing some excellent features and creating beautifully consistent prints. Though it is the most expensive of the three, I think it might be worth the money.

7.9inch 4K Monochrome LCD

Utilising an LCD to expose the resin is faster overall than the alternate laser-based printing method. This is because you no longer have to wait for the laser to follow a path around the build platform, like an FDM printer. Instead, each layer is exposed for the same amount of time, no matter how big the layer actually is. As a result, the print time increases proportionally to the print height.

| Model name | One | One Pro | One Plus |

| Screen size (inch) | 5.96 | 7.04 | 7.9 |

| LCD type* | 2K | 3K | 4K |

| LCD resolution | 2560×1620 | 2560×2400 | 4320×2560 |

| Screen Pixels Per Inch | 508.31 | 498.45 | 635.64 |

| XY accuracy/ Dot Pitch (mm) | 0.05 | 0.051 | 0.04 |

| Illumination | 3800 um/cm2 ** | 6000 um/m2 | 4500 um/m2 |

| “Evenness”/”Uniformity” | 80% and above | 90% and above | 90% and above |

*The “LCD Type” data given here is arbitrary and incorrect, but it provides a good idea of the approximate size increase between the three displays.

** Data from Creality’s website, I think the unit here is a typo

This new larger LCD directly increases the build volume of the Halot One Plus, but Creality has managed to pull this off without affecting the overall quality of the LCD panel. As a result, the One Plus’ build volume is now an impressive 172×102×160mm.

Creality also managed to increase the PPI by over 100 pixels and reduce the Dot Pitch (distance between pixels) by 0.01mm. This doesn’t sound like much, but when working at such a microscopic scale, every little difference matters.

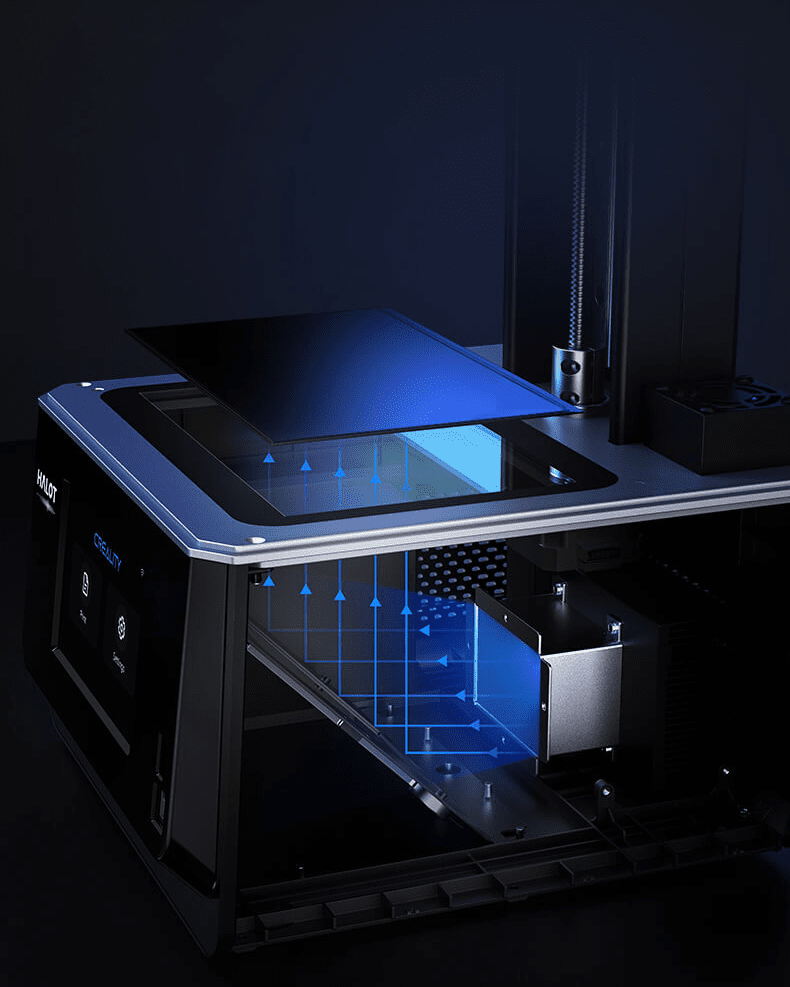

Self Developed Integrated light source

Creality has developed its own integrated light source to increase light uniformity across the whole display. Depending on the light source, a display can experience a vignette effect, having darker edges, potentially causing a print to fail. Reflecting and refracting an array of Ultraviolet lights, the Halot One Plus claims a light evenness of 90% or more.

This light source is used as the backlight for the Monochrome LCD display. Traditionally, resin printers would use an RGB display, similar to the one you’re reading this review on. However, in an RGB display, the UV light has to pass through multiple layers of liquid crystal, dimming the light. This is where a monochrome display comes in, the light only needs to pass through one layer of liquid crystal, so the UV light is dimmed significantly less. This reduces exposure time, reducing print time.

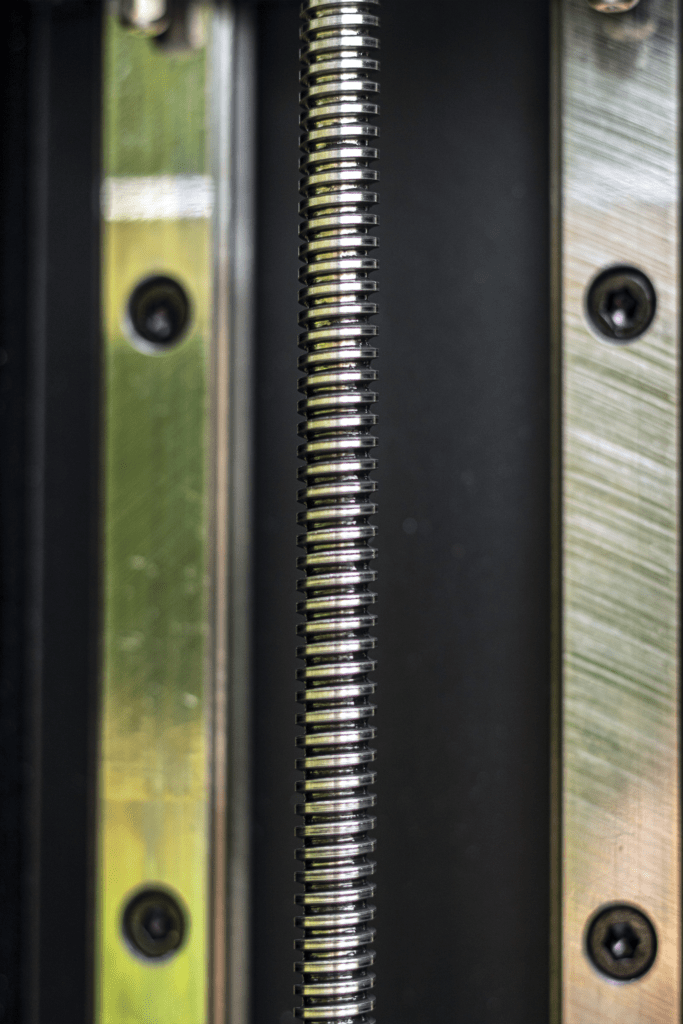

Z-axis Dual Linear Rails

As per an LCD-based resin printer, the Halot One Plus only has one moving part, the build plate. This is attached to the printer’s body via two linear rails and a type T screw. These additional supports make the platform incredibly stable, so much so that Creality claim there to be “no printer layer deviation.”

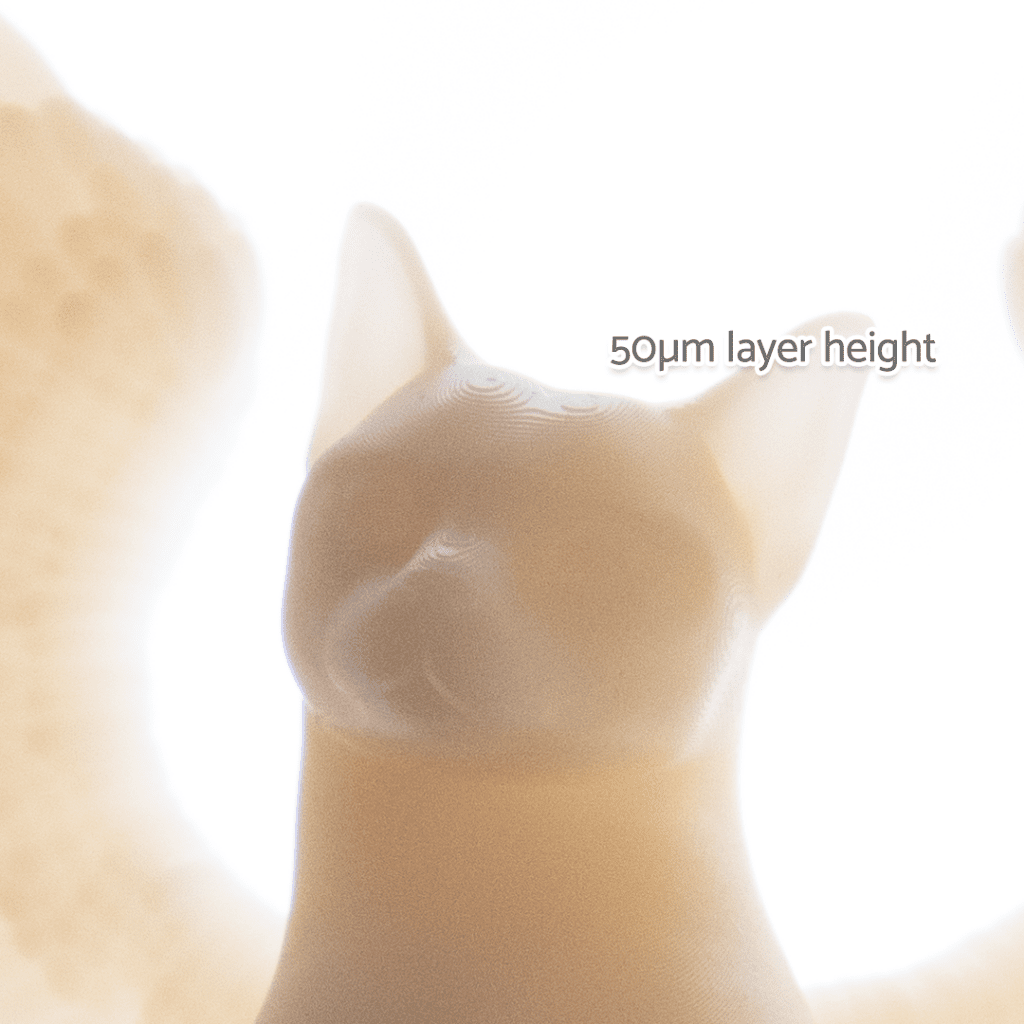

I think this is a very impressive claim to make, but it would explain why the One Plus can reach a minimum layer height of just 10μm (0.01mm). To put this into perspective, this is the same thickness as a single layer of cling film (saran wrap).

Slicer Compatibility

The Halot One Plus is compatible with various slicers, notably Halot Box, Chitubox and LycheeSlicer. Halot Box is designed to work directly with Creality’s resin printers and integrate with their Creatily Cloud service. I found Halot Box very similar to Chitubox; however, manually adding supports to the model was significantly trickier. Ultimately, I decided to add my supports via Chitubox, export the model as an STL and slice it via Halot Box. This seemed to get the best of both worlds, as I could also trust the settings profiles for the One Plus from Halot Box to get the perfect exposure settings.

Wifi and Creality Cloud

In theory, after slicing my model on Halot Box, I am then able to upload the slice to Creality Cloud. Creality Cloud is their new all-in-one service which allows you to get models, slice, and start prints all online. All wifi-enabled printers from Creality can use this service, and once you get your head around the website/ app, it’s relatively simple to use.

Available on the website is a growing collection of free-to-use models which can be downloaded or sliced on the app or in a browser. You can also upload slices directly from your computer to your 2gbs free storage.

Unfortunately, for some unknown reason, the Halot One Plus sent to me did not have wifi enabled. Included in all promotional material, manuals and descriptions, I should have had access to this feature; alas, I did not.

I have, however, used Creality Cloud’s features whilst reviewing the Sermoon V1 Pro. This review will be live within the next couple of weeks.

5-inch Large Touch Screen

The Halot One Plus is controlled via a 5-inch colour touchscreen display, complete with a little dancing logo on start up. The UI is simple and relatively easy to navigate. In addition, it provides the option to change print and exposure settings after slicing, which is a nice quality-of-life feature. To tackle these 4K printing files and powering this printer is an ARM Cortex – M4 processor with a 64bit Quad-Core CPU/GPU.

The only real point of note about the UI is that the only method of moving the x-axis is to enter the auto-levelling settings and either start or stop the movement up or down.

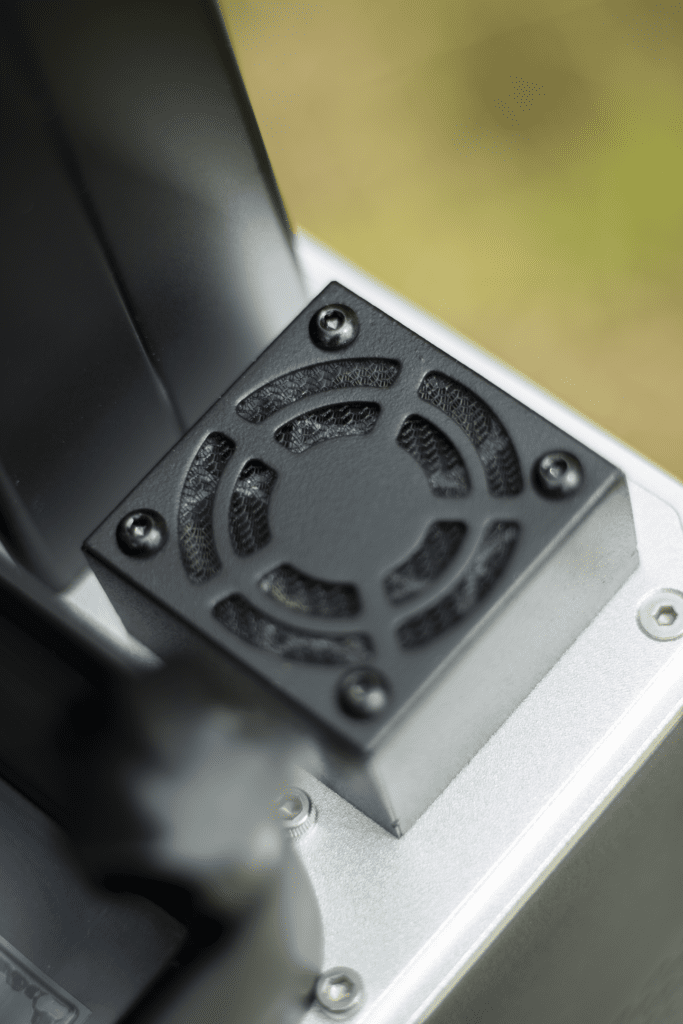

Air Filtration

Quietly in the corner is a surprisingly important feature of the Halot One Plus, the activated carbon air filter. This helps remove the fumes from the printer by a significant margin; resin can be surprisingly dangerous without adequate safety precautions. Though I will add this filter doesn’t substitute suitable ventilation in the printing room.

Easy Levelling

Levelling on a resin printer is entirely different to an FDM machine, and it’s a surprisingly basic system but so much easier. In newer FDM printers, they’re developing fancy new sensors and gauges to assess the build volume height at multiple points and micro-adjust the z-axis accordingly. But none of this is necessary on the Halot One Plus. Simply loosen the screws on the build platform, insert the “levelling card” above the display, lower the platform completely, hold the platform down to the card and tighten the screws. It’s that straightforward. As the One Plus only has one moving part, claiming to have no z-axis inaccuracy, once you’ve levelled the printer, you’re good to go.

Resin Tray

The resin tray is a similar well-designed, low-tech part of the One Plus. Though it seems arbitrary to mention it, it’s a fundamental part of the printer. Complete with a spare FEP sheet, the metal tray is the centrepiece, really. The tray is secured by two thumb screws, allowing easy removal whilst wearing gloves. It also has clear measurement lines, and two spouted corners for easy resin decanting. Again, these seem like tiny things, but they improve the quality of life when using this printer.

Overall

Overall, I was very impressed with the Halot One Plus; a lot of thought and attention to detail has gone into this machine’s design, which may not be too apparent at first glance. This printer provides superb quality at a reasonable price range; I don’t know how Creality can top this.

Buy from the official UK Agent Technology Outlet

Creality Halot One Plus Review Rating

Summary

This printer provides superb quality at a reasonable price range

Overall

90%-

Overall - 90%90%

I’m Ted Culshaw, a dedicated professional adept in the realm of film, photography, and 3D design. As the brother of the chief editor at Mighty Gadgets, James, I’ve had the privilege of overseeing the reviews for a wide range of 3D printers and creative products, covering everything from photography to lighting. My academic background in film and photography, coupled with a brief stint in the TV industry, has provided me with a rich foundation in these fields, which I leverage to consistently deliver high-quality reviews.

In my current role at my father’s bespoke kitchen business, Culshaw Kitchen Makers, I am responsible for creating many of the 3D designs and CNC cutting, thereby directly contributing to the beauty and functionality of our handmade kitchens. I take immense pride in my work, and I am constantly seeking ways to improve and innovate.

Aside from this, my passion for photography and filmography extends beyond my professional life. I regularly offer freelance services to local businesses, using my skills to help them elevate their visual presence and narrate their unique stories.

At heart, I am a passionate professional who believes in the transformative power of creative design and visual storytelling. Whether it’s through reviewing the latest 3D printer or crafting a bespoke kitchen design, I am committed to delivering excellence in all my endeavours.

You can find me on Instagram